Blog / Millinery Wire FAQs

Millinery Wire FAQs

Getting Started with Millinery Wire

Millinery wire is one of the most basic materials in hat making and has a multitude of uses. It comes in a range of sizes and materials, so knowing what kind to use for a specific project can be confusing at first. Here are answers to some of the most common questions that people ask about millinery wire when they start making hats…

What is millinery wire used for?

Wire is most often used in millinery for creating shape and reinforcing hat brims, and for constructing hat frames. Beyond brims, millinery wire can be used to create extravagant frameworks for headpieces, to give feathers the illusion of floating, or as a stem for a handmade flower. It can also be wrapped with tulle or other fabric to give the wire a foundation for sewing, or to match a design.

What type of wire is best for hat making?

The size and type of millinery wire you need will depend on what you want to use it for. Standard millinery wire is made from galvanized steel covered with either cotton, rayon or paper. There are also other specialized types of wire for hat making. Transparent polypropylene, sometimes called brim reed, is a form of memory wire often used to give hat brims a more flexible shape. Steel spring wire, another type of memory wire, can also be used to create flexible brims and hat shapes.

What gauge do I need?

The thing to remember about wire is that the larger the number the smaller the wire! Generally, the most popular sizes of millinery wire are (from smallest diameter to largest) 23 gauge, 19 gauge, and 16 gauge. Here is a little more information about each of these:

- 23 gauge – Useful for flower making or more detailed, lighter work.

- 19 gauge – A great general-purpose millinery wire, sometimes referred to as standard or firm.

- 16 gauge – Extra firm and used for more structural foundation work.

Thankfully, millinery wire is fairly inexpensive, so it is nice to keep a small variety of wire on hand for making different projects.

Should I choose wire covered with cotton or rayon?

Cotton covered millinery wire is available in black or white. I find that the cotton covering does not dye well, although it can be colored using permanent fabric markers. These are great for making your wire match the other materials in your hat or fascinator so it isn’t as noticeable. The rayon covered wire dyes very well, and has a smoother, even finish to it. It is great for making headbands to secure headpieces to the head, especially where the wire is exposed or part of the design. Rayon covered millinery wire is more expensive though, so cotton covered wire is more cost effective for general use.

How do I join wire?

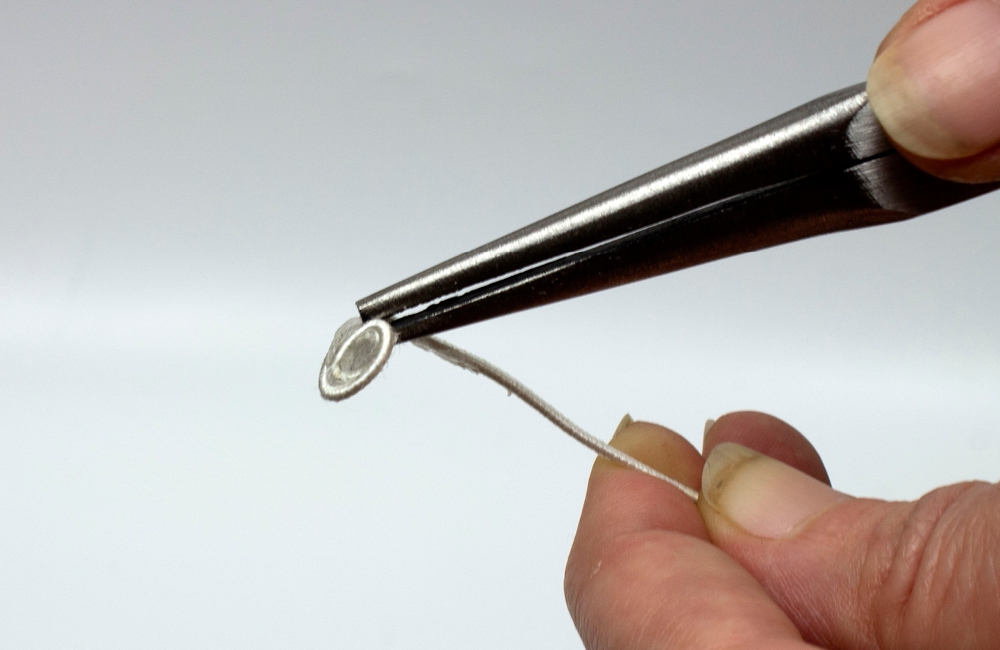

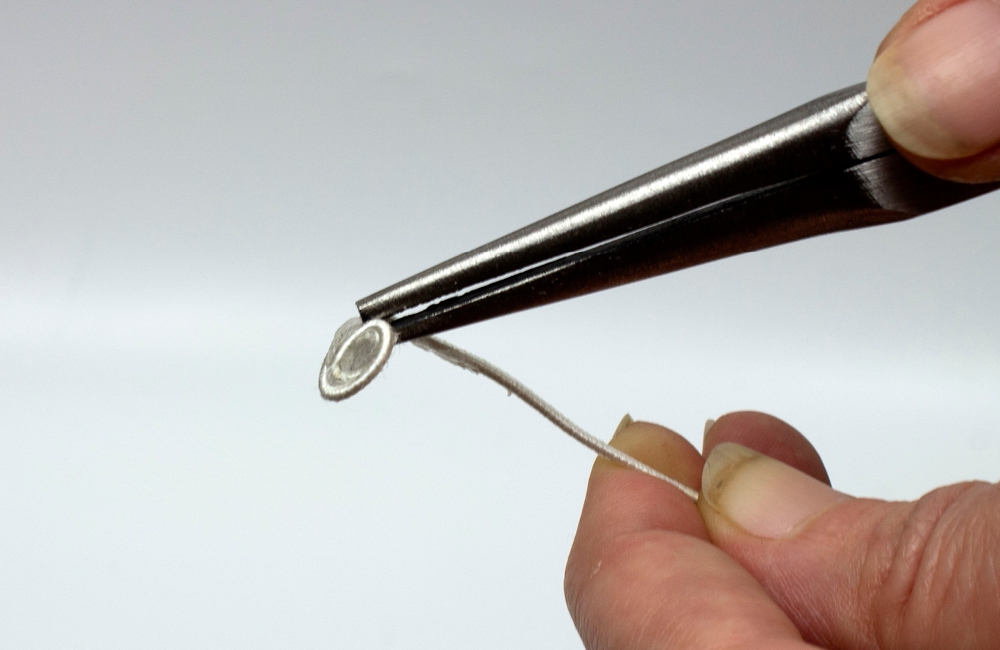

Joiners, or ferrules, can be used to connect with two ends of a piece of millinery wire when you are making a circular or oval shape to go around the edge of a hat brim. These can be heat sealed or crimped using locking pliers, depending on their material. Metal joiners sometimes rust or break over time, though, so I find a more secure way to join your ends is by wrapping them together with a strong millinery (or doubled) thread. Tape (like the kind made by Scotch or Cellotape) is also used by some milliners to join wire ends.

Where can I get millinery wire?

Becoming comfortable working with and shaping millinery wire will enable you to create stronger foundations for your hats. What I really like about working with wire, though, is the creativity that it can inspire. By using wire techniques in combination with blocking and trims, an endless array of shapes can be created.

Wire for hat making can be purchased from specialist millinery suppliers like Humboldt Haberdashery. Check the HATalk Directory to find suppliers near you.

About the Author

Amy Fowler is the creator of the bespoke, California-based Millinery by Amy Fowler label. She also runs Humboldt Haberdashery, an online millinery supplier.

See Amy’s full bio HERE.

Popular Articles

Latest e-Magazine

Featured Supplier

Millinery Wire FAQs

Getting Started with Millinery Wire

Millinery wire is one of the most basic materials in hat making and has a multitude of uses. It comes in a range of sizes and materials, so knowing what kind to use for a specific project can be confusing at first. Here are answers to some of the most common questions that people ask about millinery wire when they start making hats…

What is millinery wire used for?

Wire is most often used in millinery for creating shape and reinforcing hat brims, and for constructing hat frames. Beyond brims, millinery wire can be used to create extravagant frameworks for headpieces, to give feathers the illusion of floating, or as a stem for a handmade flower. It can also be wrapped with tulle or other fabric to give the wire a foundation for sewing, or to match a design.

What type of wire is best for hat making?

The size and type of millinery wire you need will depend on what you want to use it for. Standard millinery wire is made from galvanized steel covered with either cotton, rayon or paper. There are also other specialized types of wire for hat making. Transparent polypropylene, sometimes called brim reed, is a form of memory wire often used to give hat brims a more flexible shape. Steel spring wire, another type of memory wire, can also be used to create flexible brims and hat shapes.

What gauge do I need?

The thing to remember about wire is that the larger the number the smaller the wire! Generally, the most popular sizes of millinery wire are (from smallest diameter to largest) 23 gauge, 19 gauge, and 16 gauge. Here is a little more information about each of these:

- 23 gauge – Useful for flower making or more detailed, lighter work.

- 19 gauge – A great general-purpose millinery wire, sometimes referred to as standard or firm.

- 16 gauge – Extra firm and used for more structural foundation work.

Thankfully, millinery wire is fairly inexpensive, so it is nice to keep a small variety of wire on hand for making different projects.

Should I choose wire covered with cotton or rayon?

Cotton covered millinery wire is available in black or white. I find that the cotton covering does not dye well, although it can be colored using permanent fabric markers. These are great for making your wire match the other materials in your hat or fascinator so it isn’t as noticeable. The rayon covered wire dyes very well, and has a smoother, even finish to it. It is great for making headbands to secure headpieces to the head, especially where the wire is exposed or part of the design. Rayon covered millinery wire is more expensive though, so cotton covered wire is more cost effective for general use.

How do I join wire?

Joiners, or ferrules, can be used to connect with two ends of a piece of millinery wire when you are making a circular or oval shape to go around the edge of a hat brim. These can be heat sealed or crimped using locking pliers, depending on their material. Metal joiners sometimes rust or break over time, though, so I find a more secure way to join your ends is by wrapping them together with a strong millinery (or doubled) thread. Tape (like the kind made by Scotch or Cellotape) is also used by some milliners to join wire ends.

Where can I get millinery wire?

Becoming comfortable working with and shaping millinery wire will enable you to create stronger foundations for your hats. What I really like about working with wire, though, is the creativity that it can inspire. By using wire techniques in combination with blocking and trims, an endless array of shapes can be created.

Wire for hat making can be purchased from specialist millinery suppliers like Humboldt Haberdashery. Check the HATalk Directory to find suppliers near you.

About the Author

Amy Fowler is the creator of the bespoke, California-based Millinery by Amy Fowler label. She also runs Humboldt Haberdashery, an online millinery supplier.

See Amy’s full bio HERE.