Blog / Specialty Sheet Thermoplastics for Millinery

Specialty Sheet Thermoplastics for Millinery

More Thermoplastics for Millinery

Worbla’s Specialty Sheet Plastics

So far, in this series on thermoplastics for millinery, we have been looking at products that are available from two of the main manufacturers, Wonderflex World and Worbla.

Last time, we looked at the Worbla line of standard sheet thermoplastics. Now we will go over their specialty sheet plastics – Mesh Art, TranspArt, FlameRedArt and Kobracast Art.

Mesh Art

Worbla’s Mesh Art is a mesh reinforced specialty sheet thermoplastic similar to Wonderflex. It has a light brown color and a leather-like finish on one side. It is unique in that it is partially made from recycled rice husks. The mesh backing makes this plastic tear-resistant, so it works well for reinforcing areas with holes (like grommets) and other stretching or pulling. It is workable at 175°-195° Celcius and can be reheated endlessly. Like the standard sheet plastics, it is self-adhesive and moldable.

TranspArt

TranspArt is a clear plastic that can be hand-formed and vacu-formed. It is lighter than acrylic sheeting and more durable that PETG so it is resistant to cracks and fracturing. It has a unique flexibility compared to other thermoplastics – it can flex and return to form when bent. This plastic is not optically clear, so it is not suggested for eyewear. It is injection molded so there are some lines in the sheeting but they can be worked around. It takes a higher heat to work with this plastic, around 250°C, so smooth gloves and tools are helpful to shape it. TranspArt will become cloudier as you work with it and it is not very self-adhesive, so creating millinery with this specialty sheet thermoplastic can be a little more difficult.

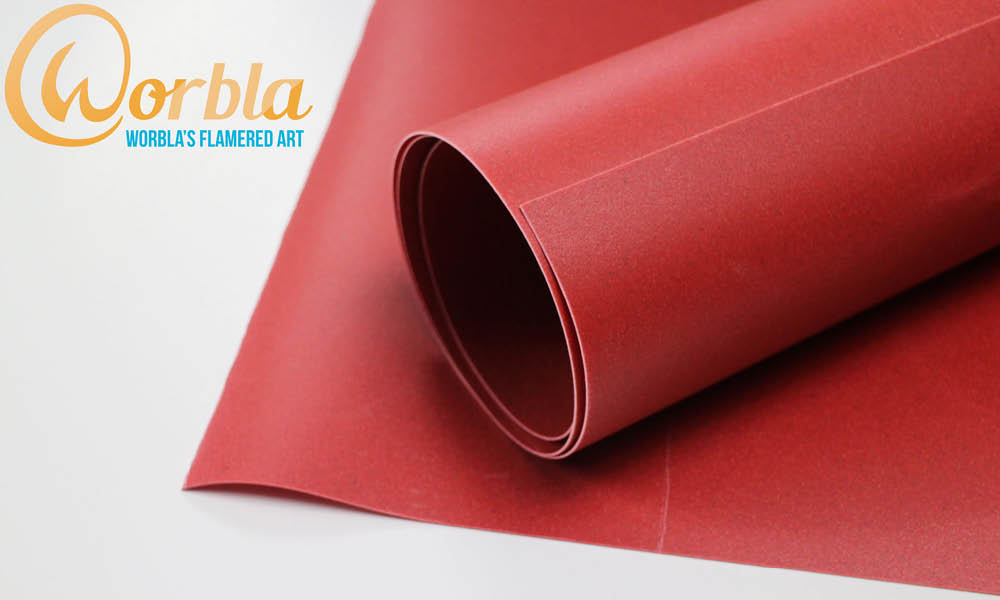

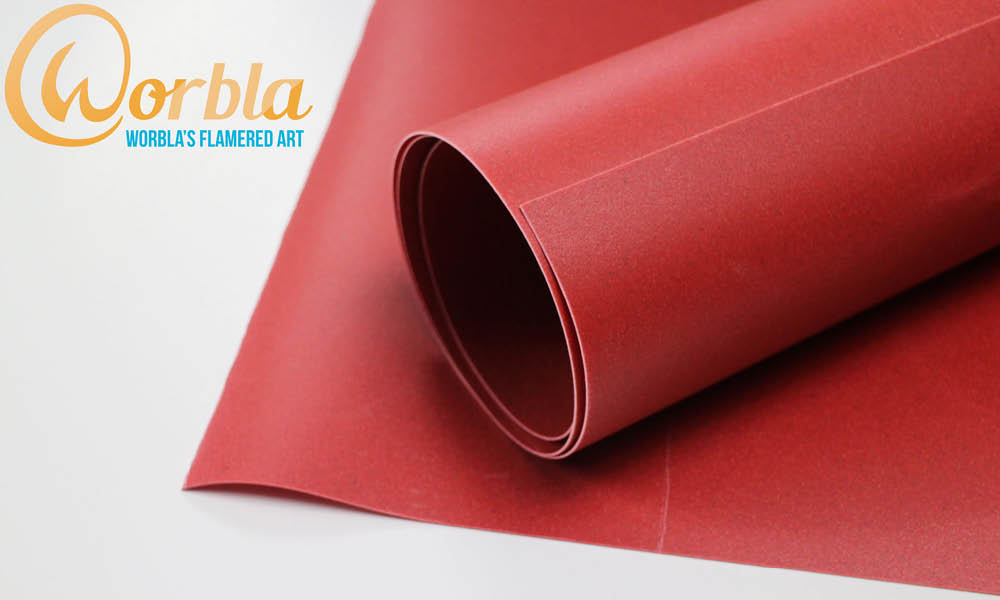

FlameRedArt

A newish product to the Worbla line is FlameRedArt. Designed specifically for theater production, it has a certified flame retardant built into it. It has a similar consistency to Finest Art (in that it is self-adhesive and moldable) but is bright red. It is more expensive because of the fire retardant used, so it is generally reserved for projects where fire resistance is needed.

Kobracast Art

The last specialty sheet plastic Worbla produces is Kobracast Art. It is the thinnest and lightest weight of their sheet plastics. It has a very strong adhesive, so it sticks well to itself and other materials. It is also very stretchable but is still tear-resistant as it has a mesh reinforcement. The thinness and flexibility make it possible to cast complex molds. Its surface is similar to medical gauze, so it needs to be primed before painting for a smooth surface. The thin texture can be sewn through, so it can be used as a stabilizing structure for fabric headpieces and trims.

Worbla’s specialty sheet thermoplastics are normally used for specialty millinery and cosplay projects and they have lots of interesting applications. Working with thermoplastics is a very experimental process. By playing with different materials you can create new techniques and original ideas all your own.

Note: The photo above (and the one at the top of the page) show millinery students at London Hat Week use silk and Kobracast Art to create delicate hand-painted orchids. These images were taken by Sara Jane Photography. All other images used in this article are the property of www.worbla.com.

About the Author

Amy Fowler is the creator of the bespoke, California-based Millinery by Amy Fowler label. She also runs Humboldt Haberdashery, an online millinery supplier.

See Amy’s full bio HERE.

Popular Articles

Latest e-Magazine

Featured Supplier

Specialty Sheet Thermoplastics for Millinery

More Thermoplastics for Millinery

Worbla’s Specialty Sheet Plastics

So far, in this series on thermoplastics for millinery, we have been looking at products that are available from two of the main manufacturers, Wonderflex World and Worbla.

Last time, we looked at the Worbla line of standard sheet thermoplastics. Now we will go over their specialty sheet plastics – Mesh Art, TranspArt, FlameRedArt and Kobracast Art.

Mesh Art

Worbla’s Mesh Art is a mesh reinforced specialty sheet thermoplastic similar to Wonderflex. It has a light brown color and a leather-like finish on one side. It is unique in that it is partially made from recycled rice husks. The mesh backing makes this plastic tear-resistant, so it works well for reinforcing areas with holes (like grommets) and other stretching or pulling. It is workable at 175°-195° Celcius and can be reheated endlessly. Like the standard sheet plastics, it is self-adhesive and moldable.

TranspArt

TranspArt is a clear plastic that can be hand-formed and vacu-formed. It is lighter than acrylic sheeting and more durable that PETG so it is resistant to cracks and fracturing. It has a unique flexibility compared to other thermoplastics – it can flex and return to form when bent. This plastic is not optically clear, so it is not suggested for eyewear. It is injection molded so there are some lines in the sheeting but they can be worked around. It takes a higher heat to work with this plastic, around 250°C, so smooth gloves and tools are helpful to shape it. TranspArt will become cloudier as you work with it and it is not very self-adhesive, so creating millinery with this specialty sheet thermoplastic can be a little more difficult.

FlameRedArt

A newish product to the Worbla line is FlameRedArt. Designed specifically for theater production, it has a certified flame retardant built into it. It has a similar consistency to Finest Art (in that it is self-adhesive and moldable) but is bright red. It is more expensive because of the fire retardant used, so it is generally reserved for projects where fire resistance is needed.

Kobracast Art

The last specialty sheet plastic Worbla produces is Kobracast Art. It is the thinnest and lightest weight of their sheet plastics. It has a very strong adhesive, so it sticks well to itself and other materials. It is also very stretchable but is still tear-resistant as it has a mesh reinforcement. The thinness and flexibility make it possible to cast complex molds. Its surface is similar to medical gauze, so it needs to be primed before painting for a smooth surface. The thin texture can be sewn through, so it can be used as a stabilizing structure for fabric headpieces and trims.

Worbla’s specialty sheet thermoplastics are normally used for specialty millinery and cosplay projects and they have lots of interesting applications. Working with thermoplastics is a very experimental process. By playing with different materials you can create new techniques and original ideas all your own.

Note: The photo above (and the one at the top of the page) show millinery students at London Hat Week use silk and Kobracast Art to create delicate hand-painted orchids. These images were taken by Sara Jane Photography. All other images used in this article are the property of www.worbla.com.

About the Author

Amy Fowler is the creator of the bespoke, California-based Millinery by Amy Fowler label. She also runs Humboldt Haberdashery, an online millinery supplier.

See Amy’s full bio HERE.